The compound fertilizer granulation equipment that can make npk fertilizer pellets

NPK compound fertilizer granulation equipment is the main machine to make npk granular fertilizer. Thus, for getting npk fertilizer pellets, you should use the npk fertilizer pelletizer machine. In SEEC heavy industry technology, we provide all kinds of npk granule fertilizer granulators for you. Such as npk fertilizer double roller extrusion granulator, npk compound fertilizer disc granulator and npk compound fertilizer rotary drum granulator, etc. These npk fertilizer granule machines can help you get high quality npk fertilizer particles in a short time. And different npk fertilizer pellets making machines have different characters and working principles. Thus, if you apply the npk fertilizer granules making machine, that will help you get more profit.

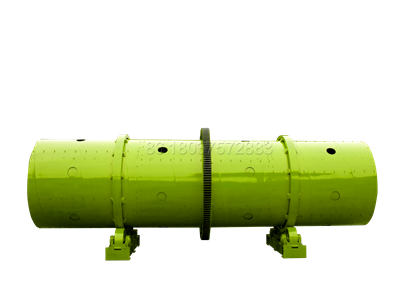

Roller drum manure pelletizer for sale

- Model:SEECZGZ-2080 (can be customized)

- Power(kw): 18.5

- Diameter(mm): 2000

- Length(mm): 8000

- Installation angel: 2°-5°

- Capacity(t/h): 8-15

Choosing a npk fertilizer pellets machine with reasonable price

Generally speaking, in your compound fertilizer granules plant, the first thing to consider is the pellet making machine. Then you need to know the price of the npk compound fertilizer granulation equipment. As stated above, SEEC compound fertilizer machinery has some npk fertilizer granulators with different prices. To be honest, if you want to know the price of npk fertilizer pellets machine, you should provide your budget for us. And the area of your fertilizer plant is also important. For example, if your space is limited, you should install a small-scale npk fertilizer granulator in your npk fertilizer production plant. And the price of this npk fertilizer pellets machine is lower than others. With this information, we can recommend you a suitable price of npk fertilizer granule machine.

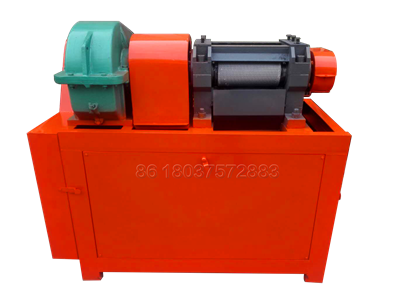

Two roller extrusion granulator for sale

- Model: SEECWJ-2T(can be customized)

- Power(kw): Granule diameter≤4.5m: 22

- Granule diameter>4.5m: 30

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 185×300

- Diamensions(mm): 1630×850×1650

SEEC hot sale npk fertilizer granulator machine for sale

Npk fertilizer double roller extrusion granulator is the most popular granulator of all npk fertilizer granule granulators. Do you know why this double roll extrusion granulator is selling well? Here are the reasons why our customer chooses this pellet making machine.

- This npk compound fertilizer granulation equipment belongs to dry type granulation. So you don’t need to use rotary drum drying machine and rotary drum cooling machine to remove the moisture of the npk fertilizer pellets. That will save your production time and the costs of cooling machine and drying machine.

- You can choose various particle shape by using npk fertilizer double roller extrusion granulator. Such as pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat shape and square bar shape, etc.

- In addition, SEEC npk fertilizer double roller extrusion pellet making machine is the specialized equipment for making npk fertilizer. Thus, this granulator is more efficient and professional. If you want to know more information about our npk compound fertilizer granulation equipment. Feel free to contact us.

Double roller fertilizer pelletizer for making npk fertilizer pellets

- Model: SEECWJ-1.5T(can be customized)

- Power(kw): Granule diameter≤4.5m: 18.5

- Granule diameter>4.5m: 22

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 150×300

- Diamensions(mm): 1450×850×1500

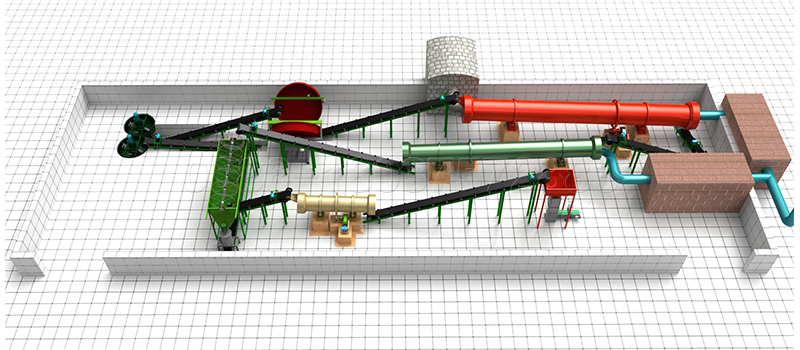

SEEC rotary drum granulator for making npk fertilizer

Except double roller extrusion granulation, we still have another fertilizer making machine-rotary drum granulator to make npk fertilizer granules. Compared to double roller extrusion granulator, there are some different characters.

- With rubber engineering plastics as the lining, raw materials are not easy to stick to the cylinder. Rubber engineering plastics can also play a role in anti-corrosion insulation.

- This npk fertilizer rotary drum granulator still has the character of large output, low power consumption and low maintenance cost.

- The npk fertilizer pellets formation rate is up to 70%, with a small amount of return material. And the return material size is small, which can be re-granulated.

- In addition, by using drum granulation method to make npk fertilizer, whether the powdery fertilzers are in a temperature lower or higher than the room temperature, you can make granular npk smoothly.

Rotary drum granulator for making compound fertilizer pellets

- Model:SEECZGZ-1560 (can be customized)

- Power(kw): 11

- Diameter(mm): 1500

- Length(mm): 6000

- Installation angel: 2°-5°

- Capacity(t/h): 3-5

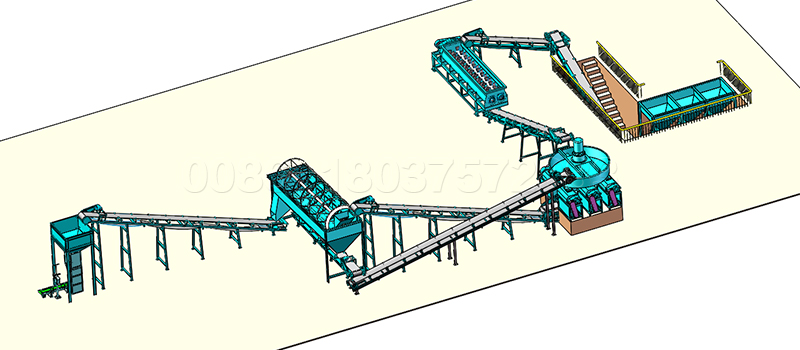

How to make npk compound fertilizer granules? Here are the npk granular fertilizer making processes?

Do you want to know how to make npk compound fertilizer granules? Next we will tell you the details of making granular npk fertilizer.

- You should prepare the powdery npk fertilizer raw material. If the npk fertilizer raw material is solid, you should use a fertilizer crusher to make them into powdery. Only the powdery fertilizer can make fertilizer granules by using npk fertilizer pellet making machine.

- Then mix these powdery npk fertilizer in a certain proportion by using horizontal mixer. With the help of horizontal mixer. The npk fertilizer raw material will be mixed uniformly.

- Granulating. Here is the step of granulation. You need to put the powdery npk fertilizer into npk compound fertilizer granulation equipment. Then you will get the granular npk fertilizer after the process of granulating.

- If you adopt wet type granulation in your npk fertilizer production process, you need to use rotary drum drying machine and rotary drum cooling machine to remove the moisture of the fertilizer granules. On the contrary, if you didn’t adopt wet type granulation, you can enter the next step directly.

- Screening. Because there are some unqualified pellets after the process of granulating. You’d better use a fertilizer screen machine to sift them out. And Unqualified particles will re-enter the granulation system to make fertilizer granules.

- Packing. You can use an automatic packing machine to pack the npk granular fertilizer.

The granulation process about npk granules

For getting npk granules, we know we have to use npk compound fertilizer granulation equipment. But do you know how a double roller extrusion granulator works? Here is the process of npk fertilizer granulation.

- Firstly, with the help of conveyor belt, the mixed materail can send to the npk fertilizer double roller extruaion granulator, and the powdery materials are imported from the top of the machine.

- Then the powdery NPK fertilizer material is forced between the two rollers below for extrusion, and the rollers rotate relative to each other. Under the strong extrusion pressure, you can get cake shape material.

- Next the cake shape material can send to the crushing chamber and broken by the crushing shaft.

- Finally, the crushed material will be screened through the screen below the crushing chamber. Qualified particles are sent to the outside through the conveyor belt. And the sifted powder materials will be sent back to the raw materials warehouse for the second roll.

Pan granulator for your npk fertilizer plant

- Model: SEECYZ-1800(can be customized)

- Edge height(mm): 300

- Rotary speed(r/min): 21

- Motor power(kw): 3

- Capacity(t/h): 0.8-1.2

- Dimensions: 2060×1700×2130

SEEC NPK compound fertilizer granulation equipment has wide application

Our NPK compound fertilizer granulation equipment has wide application, and you can use it in many places. Here are the places that you can use our granular fertilizer making machine.

- Suitable for the materials in pharmaceutical industry, chemical industry, feed industry, coal industry, metallurgical industry, etc.

- Wide material resources: rare earth, ammonium carbonate, ammonium sulfate, potassium chloride, urea, ammonium chloride, potassium sulfate, ammonium phosphate, etc. To be honest, as long as your material is powdery and you want to get granular material, you can use our NPK fertilizer granulator machine.

- You can use our granular fertilizer pelletizer to make organic compound fertilizer, bio-compound fertilizer, magnetic fertilizer.

NPK compound fertilizer double roller extrusion granulator

- Model: SEECWJ-1.5T(can be customized)

- Power(kw): Granule diameter≤4.5m: 18.5

- Granule diameter>4.5m: 22

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 150×300

- Dimensions(mm): 1450×850×1500

Except wide application, what are the other advantages of NPK compound fertilizer granulation equipment?

- We have different granulation technologies for you to choose. In our fertilizer machinery, we have two different granular fertilizer making method. That is wet pelletizing process and dry pelletizing process. You can choose the suitable one for you to make fertilizer pellets.

- Compact layout, advanced technology, stable operation, easy maintenance.

- More choice in capacity, our NPK granulating machine has many different configurations in models, capacity, and appearance.

- Easy operation. SEEC highly automatic NPK compound fertilizer granulation equipment is easily to control and operate.

- Long service life. As long as you operate the NPK granulator according to the product specification, the using time will be longer than others.

- High quality. Our NPK compound fertilizer granulation equipment adopts the steel as the materials for making our NPK compound fertilizer granulator.

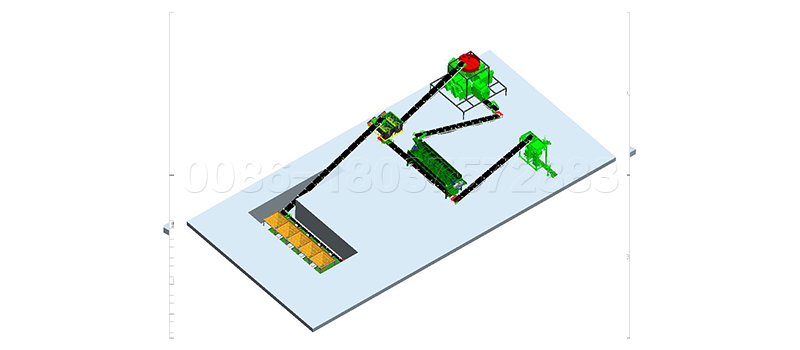

How to start a granulated compound npk fertilizer plant with the help of npk compound fertilizer granulation equipment?

As we all know, starting a npk fertilizer granulation plant, you should have npk compound fertilizer granulation equipment. But it’s not enough just have a fertilizer pellets making machine. What else should you consider?

- The cost of building npk fertilizer granules plant. No matter what plant you want to build, you should think about the cost. For example, if your budget is limited, you should choose some inexpensive npk fertilizer making equipment for your npk fertilizer granulation plant.

- Output. The second thing you should consider is how many tons of granular NPK fertilizer you want in an hour. For example, if you want to get 0.02t fertilizer pellets in an hour, you can get a small-scale fertilizer granulator. On the contrary, if you want to get 6t or 8t fertilizer in an hour, you need to have a large-scale npk compound fertilizer granulation equipment.

- Factories should be built away from the living and working areas of residents. The fertilizer factory may produce a bad smell in production. Therefore, you can’t set up the fertilizer plant in the living working area of residents, nor can it be upwind of the living working area.

Customized disk pellet mill for sale

- Model: SEECYZ-3000(can be customized)

- Edge height(mm): 450

- Rotary speed(r/min): 14

- Motor power(kw): 11

- Capacity(t/h): 2-4

- Dimensions: 3400×2400×3100

How do you choose a trustworthy npk granular fertilizer machinery manufacturer?

How can you find a trustworthy granular npk fertilizer machinery manufacturer? Here are the things that you need to know.

- First, you need to know the qualifications of the fertilizer equipment company. As a fertilizer machinery, we have over 30 years’ fertilizer machinery production experience. Therefore, you can believe that we can make high-quality compound fertilizer granulator for you.

- Secondly, it is necessary to see whether the manufacturer has advanced equipment technology or a number of professional technicians. Because only professional technical personnel can make the best fertilizer equipment and reduce the error to the minimum. In addition, when you buy the equipment and something goes wrong, they can fix it for you.

- The lasr is after sales. If a factory is qualified, we can see its after-sales service. The after-sales service personnel of the manufacturer should make a return visit at a fixed time, and then deal with the customer’s problems in the fastest time, so as to reduce the loss of the customer as much as possible.