Manure granulator is the most important equipment for making manure pellets. By using manure granulator, you can get the granulated manure easily. If you have a poultry farm or livestock farm, SEEC manure fertilizer granulator can help you a lot. With the help of granule manure machine, you not only can handle the animal dung well, but also can earn more money from it. And If you want to build an organic fertilizer production line or small-scale organic fertilizer production line, manure granulator is the main equipment that you can’t ignore. In SEEC fertilizer machinery, we have different manure pellet mills to meet your needs.

SEEC manure fertilizer granulator for sale

- Model: SEECJZ-1200 (can be customized)

- Installation angel: 2°-2.5°

- Capacity(t/h): 4-6

- Total power(kw): 90

- Moisture of feeding material: 20%-40%

- Dimensions: 4900×2550×1800

The price of manure granulator machine

In SEEC pelletizer machinery, we have many fertilizer granulators that can handle animal waste. Such as, manure new type organic fertilizer granulator, manure disc granulator, manure rotary drum churning granulator. And these manure granules machines have different prices.

Disc granulator is the smallest manure pelletizer in our company. With its small granulator plate and low output, the price of manure disc granulator is lower than others. So if your production space is limited, you can choose this granulator.

SEEC small-scale fertilizer making machine for sale

- Model: SEECYZ-1800

- Edge height(mm): 300

- Rotary speed(r/min): 21

- Motor power(kw): 3

- Capacity(t/h): 0.8-1.2

- Dimensions: 2060×1700×2130

Manure fertilizer organic fertilizer granulator. The price of SEEC manure organic fertilizer granulator is higher than disc granulator. Because we adopt the special material make this manure fertilizer pellet making machine, and the quality is higher than others.

Rotary drum churning granulator. Compared with these two fertilizer pellets granulators, the price of this granulator is more reasonable than other organic fertilizer pellets making machine. Because manure fertilizer rotary drum churning granulator is the machine that combine two different functions. With two high-efficiency functions, the hardness of fertilizer particles is higher than others.

Rotary drum stirring manure granulating machine for sale

- Model: SEECZJZ-1060

- Production capacity: 5-8 t/h

- Shape size: 7250×1250×1670

- Installation angel: 2°-2.5°

- Total power: 7.5+18.5kw

How do you make manure into fertilizer pellets?

As mentioned above, you will know that if you want to get the manure pellets, you should use a manure granulator. Do you know how to make particles? Here are the processes of making manure to granules.

If you want to get the manure pellets, the manure raw material should be powdery. Then the powdery manure fertilizer is allowed to be made into pellets by using manure granulator. That is the main step of the manure pellets production process. You should choose the right equipment to make it. Then you can operate the machine easily. You just need to put the manure material inside by conveyor belt when the switch is on. Then the fertilizer pellets will come out from the discharge port. And if you want to get chicken manure fertilizer particles, you can use a chicken manure pellet making machine.

Manure fertilizer pellets processing machine for sale

- Model: SEECYZ-3000(can be customized)

- Edge height(mm): 450

- Rotary speed(r/min): 14

- Motor power(kw): 11

- Capacity(t/h): 2-4

- Dimensions: 3400×2400×3100

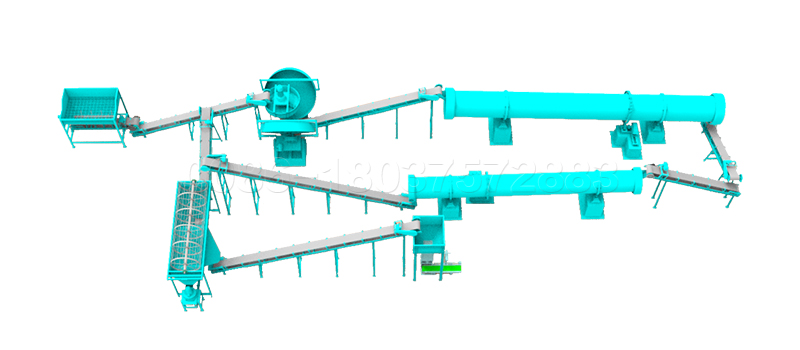

SEEC whole manure pelletizing systems is provided for you to make manure fertilizer pellet

In order to get the manure particles, you also should know the whole manure production processes.

Manure dehydration. The moisture content of manure raw material is very high. So you should dehydrate the manure raw material at the first step.

Manure composting: Unfermented fertilizers can be harmful to crops and plants. Thus, you should use a compost turner to ferment the manure raw material.

Manure crushing: The manure fertilizer maybe become solid after composting. Then use hammer mill to crush them into powder (2~5mm in diameter).

Manure granulation. As stated above, you can use manure pelletizer to get fertilizer pellets. If you you want to get cow manure fertilizer granules, our manure granulator-cow manure fertilizer pellet machine is your best choice.

Drying and cooling. If you adopt wet granulation. You should use rotary drum drying machine rotary drum cooling machine for drying the manure fertilizer pellets. The purpose of this step is to further remove water and lower the temperature of the manure particles.

Screening. There are some unqualified manure fertilizer pellets existed in the fertilizer pellets. For removing the unqualified fertilizer pellets, you can use a rotary screening machine.

Packing. To increase production efficiency and reduce production time, you should use a single bucket automatic packaging machine to package manure fertilizer pellets

In the manure granulation process, what equipment do you need to control moisture and temperature?

In manure granulation process, you need to notice the problem of moisture and temperature. Next we will discuss how to control the temperature and moisture of the manure fertilizer.

Manure fertilizer solid-liquid separator. To be honest, almost all animal manure fertilizers, such as cow poop, sheep dung, pig manure, have too much moisture inside. You can’t use these fertilizer raw material with too much water to make fertilizer particles. While a higher moisture level is permissible, any materials with more than 75-80% moisture will require mechanical separation. Therefore, you should find a method to solve this problem. In our manure fertilizer machinery, we have an equipment that can help you to reduce the moisture content of manure raw material. That is manure fertilizer solid-liquid separator. By using this manure fertilizer processing machine, you can get the fertilizer that meet moisture standards.

Granular fertilizer rotary drum cooling machine. After the process of fertilizer granulation, you will find the temperature of fertilizer pellets is too high. At this temperature, you can’t package these fertilizer particles. Then you need to cool down the temperature of fertilizer particles. At this time, fertilizer pellets cooling machine should be used to solve this problem.

Manure granulator application:

Our manure fertilizer pelletizer has wide application, it is applied to granulate all kinds of organic raw material, which turns organic waste into organic fertilizer. And the quality of manure pellets made by manure granulator also has the character of high efficiency. Thus, our manure granulator has the character of low energy consumption, low production expenses and high production quantity. Manure granulator can be used in various fertilizer granulation plant, such as, small scale organic fertilizer plant, large scale organic fertilizer factory, cattle farm, sheep farm, pig farm etc. If you have a fertilizer plant or animal farm, and want to make organic fertilizer granules from organic fertilizer raw material. Our manure fertilizer pellets making machine can help you.

How many organic fertilizer raw materials can be putted into manure granules machine?

There are many organic fertilizer raw materials can be used to make organic fertilizer. Here are the common organic fertilizer raw materials that you can use to make organic fertilizer granules.

Agriculture waste: Agriculture waste includes straw, cottonseed meals mushroom residues, bio-gas residues, fungus residue, lignin residue, palm etc.

Industrial waste: The common industrial waste includes vinegar residues, sugar residues, lees, furfural residue, manioc waste etc.

Animal manure or sludge: All of the animal poop can be used to make organic fertilizer, such as raw chicken poop, cow dung, horse manure, pig poop, drainage sludge, river sludge etc.

How many features about our manure fertilizer granulator?

Our manure fertilizer granules making machine has high granulation rate, so it can make 100% pure organic fertilizer pellets, which meets our customer’s requirements.

The granules made by our manure granulator are spherical and uniformly shaped, which has the character of high efficiency.

Fertilizer pellets making machine produces granules with high hardness, which can be screened immediately after the process of granulating.

This manure fertilizer pellets granulator has a steady performance. And our fertilizer granulator is made of anti-corrosive and wear-resistant materials and prolongs a long services life.

If you want to make manure pellets, what other things should be considered?

Flue gas

All manure granulation operations produce emissions and will require some forms of exhaust gas treatment.

According to the relevant laws and regulations, you can’t put waste gas into the atmosphere directly. Thus, you can use a water curtain dust collector to handle the flue gas. After this process, the waste gas can be putted into the atmosphere.

Spatial needs and storage

There are many things to consider in terms of spatial needs and storage for the operation. A manure granulation plant and the necessary supporting systems require a sizeable facility. Space will also need to be made for the pre-treatment (dehydrating, crushing, composting, etc.) If you don’t have enough space, SEEC designer can help you make a suitable installation plan for you. You can contact us at any time.

Electricity

Similarly, you also need to think the problem of the source of electricity. If a reliable source of electricity is unavailable, other options, such as large-scale generators will need to be considered.